Turbine Inlet Chilling

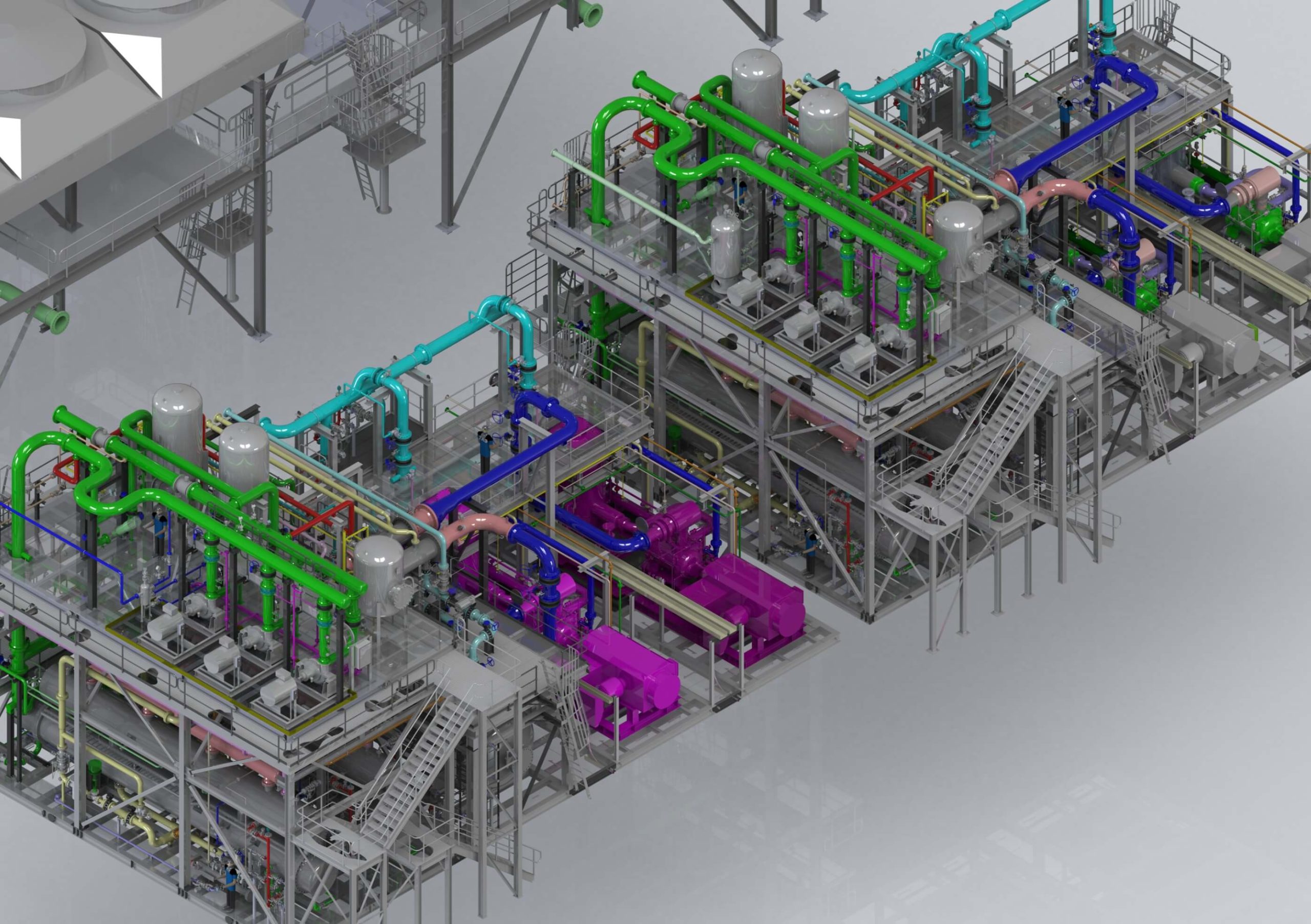

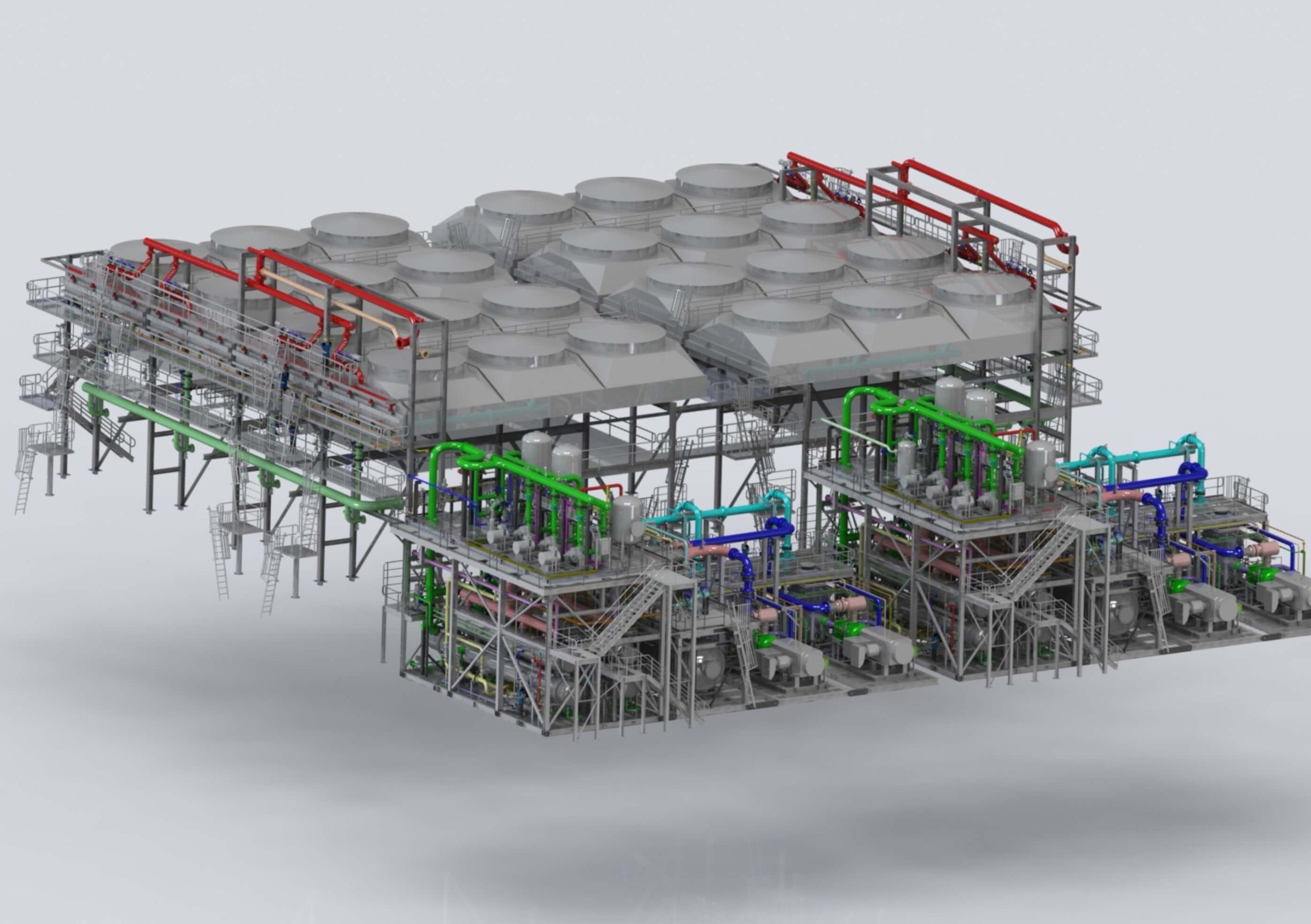

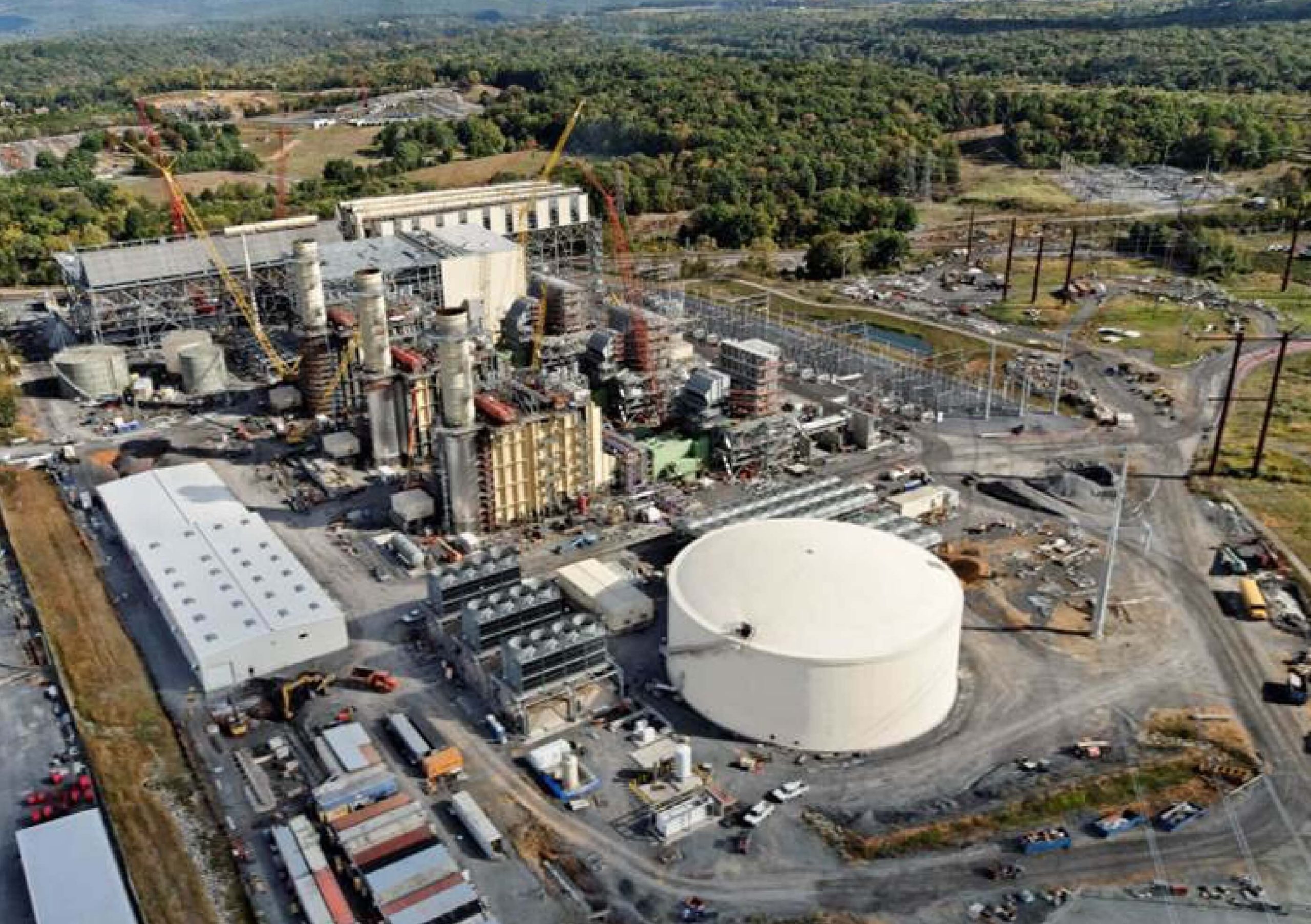

Turbine Inlet Chilling (TIC) is a proven method of cooling gas turbine inlet air to maximize the turbine output across ambient conditions. Systems can be installed in new or existing power plants. This system can use water or forced air as a form of cooling. The addition of a Thermal Energy Storage (TES) tank to the chilling system can optimize performance during the hottest part of the day. Chilled water is produced and stored at low power demand times (night) and then used during high demand times (peak hours) to maximize the power available when most needed.

Water- or Air-Cooled System

The output of all gas turbine power plants decreases in high ambient conditions. Water is utilized as the cooling medium when water is readily available in high-humidity conditions, while water can be replaced with air in less humid locations.

Features and Benefits:

- Consistent, year-round performance for ambient conditions from 47°F to 115°F (8°C to 46°C)

- Unaltered stable emissions performance throughout the operating envelope

- Peaking power at optimal CTG heat rate

- A modular solution that is designed for ease of maintenance, including built-in lifting points, floor drains, access doors, quick disconnects, built-in cableways, etc.

- Series chillers allow TAS to extract 14% to 19% more refrigeration capacity out of commercial chillers while improving energy efficiency by 12+%

- Variable turbine inlet temperature controls allow TAS to respond to rapid changes in grid load by rapidly varying the output of the gas turbine by adjusting the inlet turbine air temperature, which can supplement the variable generation caused by increased renewables

- Design to suit to the site-specific gas turbine type, weather, and operating profile

- Variable-speed pump for TIC/TES System allows the flow of chilled water from the TES tank to the TIC cooling coil to maintain T2 turbine inlet air temperature setpoints

- Full-service installation support

Thermal Energy Storage

The addition of Thermal Energy Storage to the modular chilling system can enhance performance and decrease operating costs while chilling is in operation. Chilled water can be generated and stored at low power demand times and then used during high power demand times to maximize gas turbine performance when most needed.

Features and Benefits:

- Tanks can be sized to help guarantee day-ahead performance regardless of weather

- Unaltered stable emissions performance throughout the operating envelope

- Eliminates performance risk due to ambient conditions

- Peaking power at optimal CTG heat rate reduces the parasitic loads at peak load times (chiller off)

- Cost effective renewable integration

- Designed so chilled water storage is adaptable to match power plant load fluctuations

- A modular tank build can minimize site time

- Choice of tank build materials