Central Utility Plants

What is a CUP?

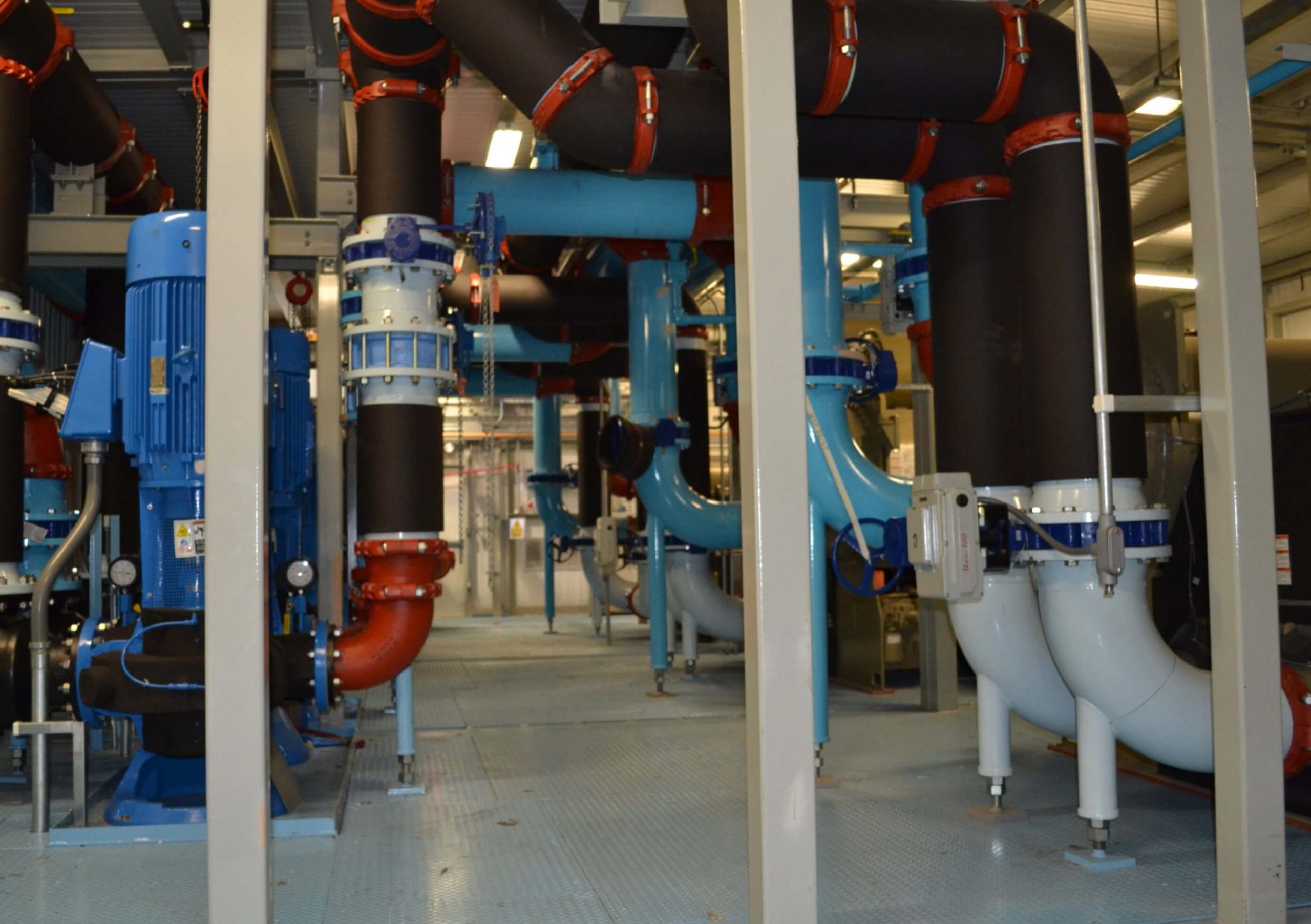

A Central Utility Plant is a contained area within a building or a separate building that houses mechanical and electrical equipment for building utilities/services such as chillers, air handlers, boilers, generators, pumps, electrical support equipment, and the like. All buildings need services. Larger factories or facilities often need chilled water or air for cooling, hot water, cooled or dry air, a mode of delivery or storage of fluids, and starting and controlling equipment. The types of facilities typically requiring such services are data centers, high-tech manufacturing facilities, hospitals, stadiums, food production, pharmaceutical production, or vehicle battery plants. These services can be designed to be fully contained in TAS modular designed solutions whether inside a larger building or in a separate building.

Benefits of Modular CUPs:

- Reduced site footprint

- Reduced job site crane costs

- Custom design to fit site-specific needs

- Reduction of labor and material management at the site

- Controlled build environment and proven quality management processes

- Build cycle optimization

- Reduction of environmental impacts to project cycle

- Considerable cost savings over conventional stick-build construction

- Tax advantages: CUPs are depreciable as assets if the modules are not normally manned

- ETL and UL labeling

- Central utilities as tie-in points

- Custom finishes that match the remaining plant design

- Pre-manufactured maintenance and operation access

- Designed to meet wind and seismic criteria of the site

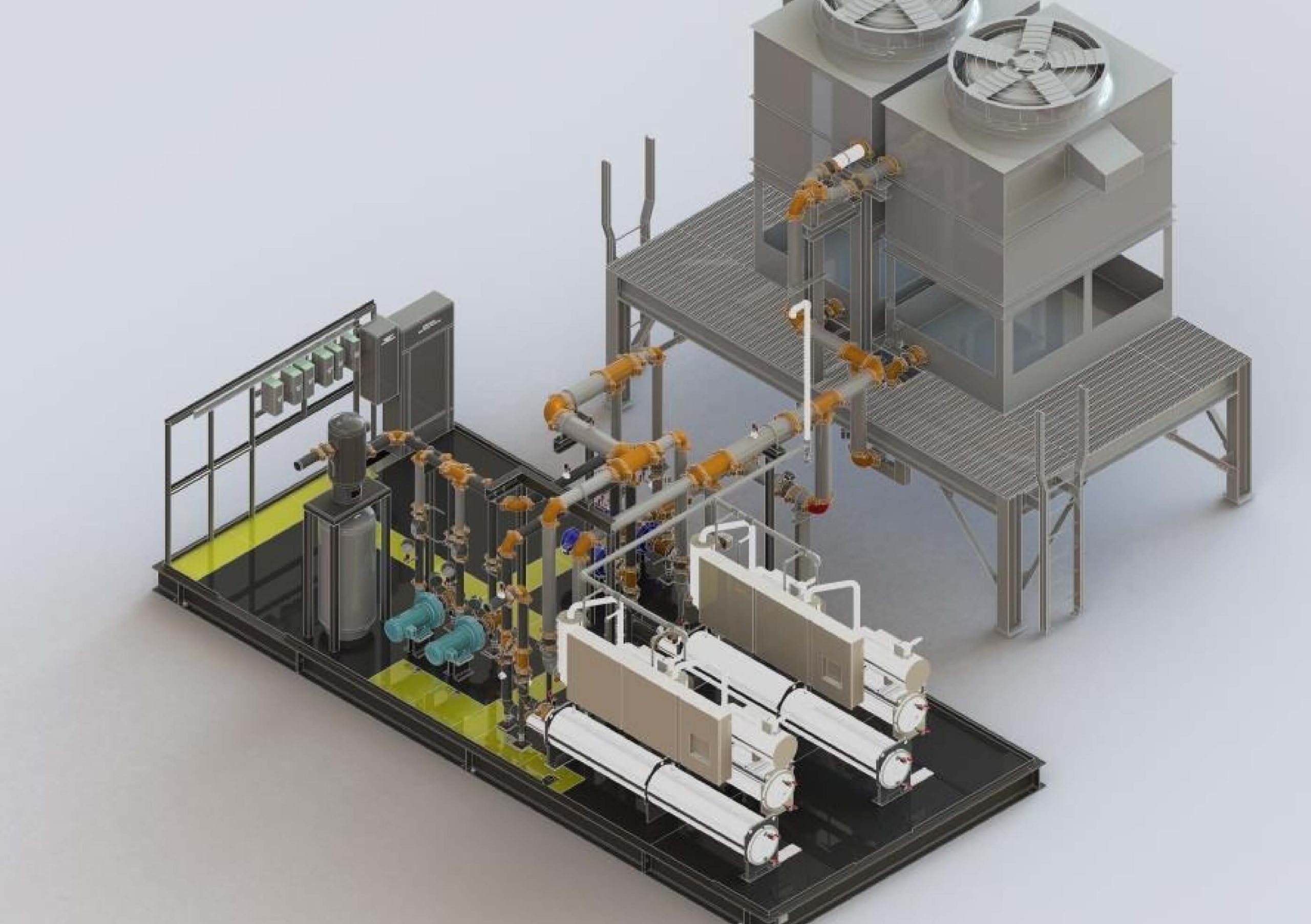

- BIM modeling

- Custom electrical and control packages

- Pre-commissioned factory testing

- Full-service installation support

Our Best-in-Class Engineering

Our TAS-certified engineers offer well over 100 years of combined experience, ensuring that every design is cost-effective, efficient, and modularized to optimize transport, installation, and operational ease where possible. The most effective solution is a design-assist approach where the client and TAS work as a team to develop the best solution for you. However, if you have a basic design, TAS can modularize it!

Industry Leading Solutions

TAS approaches every client with a cohesive, individualized plan to meet each project goal, whether it’s an existing plant upgrade, expansion, or new build. TAS works with you to find the best-engineered modular solution.

TAS carefully studies all factors to minimize the costs and schedule time while maximizing the ease of manufacture, transport, and efficiency of operation for every modular solution.

The TAS Edge

TAS is an award-winning company for a reason. We provide solutions for the ever-evolving demands of today’s industries, sharing our expertise with every client that we partner with. TAS is equipped to help solve your project challenges. We look forward to revolutionizing the way your Central Utility Plants are engineered and built. Contact us today!